An Interior Ellis Island (Print Version)

Setting the Scene

Mining Occupations

Close

Abstract

At the zenith of its productive life, Michigan’s

copper district produced over ten billion pounds of refined copper annually

and directly employed thousands of men in a variety of jobs above and below

the ground.

Although it would be impossible to describe all of the different jobs in an active mining company, it is useful to consider the major types of work required in a Michigan copper mine. The following descriptions are intended as a quick overview of the underground and surface work at an average Michigan copper mine. Work in rock stamp mills and copper smelters are not included here.

• Mining captain, assistant captains and shift bosses

• Miners and blockholers

• Contract miners, contract teams, and drill boys

• Cutters and chiselmen

• Trammers, muckers and track men

• Pickers, fillers, wallers

• Timbermen and sprinklers

• Surface superintendent, surface captain and surface bosses

• Rock house laborers, kiln men and car fillers

• Hoisting engineers, hoist tenders and wipers, landers and roll men

• Pump and compressor engineers, tenders and pipe men

• Teaming and Railroad

• Other skilled surface workers

• Diamond drill

• Change house or “Dry House”

• Watchman and firemen

• Surface laborers

• Mine superintendent / general manager

• Chief Clerk, supply clerk and assistants

• Mining engineer, geologist, assayer and assistants

• Chief engineer, engineers, architects, draftsmen

• Time keeper, stenographer & clerical assistants

Mining captain, assistant captains and shift bosses

Historically, the use of the word captain comes from a Cornish tradition in which the “man in charge of mining work” was termed a captain. The mining captain is the executive officer underground. Mining captains, assistant captains and shift bosses managed the underground work force, assigning employees to different jobs underground and taking direct oversight of all work. In the early years of Michigan’s copper mines, mining captains were almost always Cornish immigrants who brought decades of underground experience with them (in later years, the work of the experience-bred mining captain gave way to the college-educated mining engineer). mining captains are often identified in photos by their white clothing.

Underground work was overseen by a hierarchical structure of managers. A single mining captain might manage an entire mine operation, with assistant captains in charge of individual shaft or underground working area. Shift bosses were responsible for individual groups of men and might be more directly involved with actual underground work.

Not everyone who worked underground could use the title miner. In most mining settings, miner referred to the very few employees who actually operated a drill or drilling machine, filled holes with explosives and set off charges. The position of miner was considered a skilled job and was usually paid at a higher rate than other employees. In early years, drilling was done by hand (with hammers and hand steels) and black powder was inserted in the finished holes. Later years saw the introduction of machine drills, nitroglycerine and dynamite. Some immigrants to Michigan’s copper district brought mining skills from districts in their home countries. Throughout the Keweenaw’s history, Cornish immigrants held a large number of jobs as miners. But Irish and German immigrants also emerged in these skilled roles and, in later years, underground workers of other ethnicities rose through the ranks to the position of miner.

In come cases an initial explosion created pieces of rock that were too large to move. Men known as blockholers would drill and blast these rocks into smaller pieces. Blockholers were also given the dangerous job of drilling and blasting rock which had become jammed in chutes or special tunnels for passing rock from one level to another. The work of the blockholer, though requiring the skillset of a miner, was considered more dangerous particularly when clearing rock chutes.

Contract miners, contract teams, and drill boys

Many miners worked on a contract – and were known as “contract miners” – and agreed to sink shafts, “drift” (excavate underground tunnels) or “stope” (remove copper rock within the mine). Rather than being paid a regular hourly or monthly salary, these contract miners were paid negotiated price for each foot or cubic fathom removed; the more work they did, the more work they could receive. Contract miners usually worked in teams of 4-6 men, with contracts negotiated and paid on a monthly basis. The contract system was imported by Cornish miners, but contract teams in Michigan mines included teams from many different ethnic groups. Teams often included several members of an extended family.

Most contract teams included a drill boy, whose job was to retrieve supplies (including replaceable drill steels) from the shaft and deliver them to the men working the drills. Drill boys earned about half the money that a skilled miner might earn. Very often, a drill boy was the son of a member of the contract team and eventually moved up to fill a regular position alongside his father or uncles.

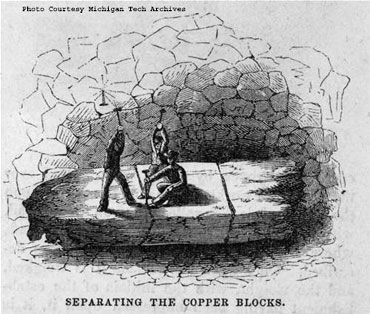

Geologically, Michigan’s copper mining district differed from other mining because the ores in the Keweenaw featured copper in its native metallic form. Rather than forming in sulfide or oxide compounds which required different types of chemical separation and smelting technologies, Michigan’s “native copper” deposits were invested with pieces of actual copper metal. In most lodes, these pieces of copper were just tiny flecks of metal disseminated through the surrounding rock, sometimes composing less than 3% of the total. In other places, large masses of pure copper formed, some weighing hundreds and thousands of pounds. Although profit could be made from these masses of copper, a different type of workman was needed to remove them from the underground mines.

The copper was too soft to blast with explosives, so the masses had to be separated into smaller pieces which could be removed from the mine. In the early years, chiselmen would be employed; using a flat-edged chisel and hammer, these men would cut a long groove along the face of the copper (often producing beautiful “copper fans” as they chiseled off long bands of metallic copper). Once the groove was deep enough, pry bars or small explosive charges could be used to break the smaller chunks away. In later years, cutters were employed to work masses of copper. Using pneumatic chisel hammers, these men would cut through the mass of copper. In other mines, holes were drilled right through the copper masses using a pneumatic twist drill. Forming a line of holes along an edge, explosives could be used to dislodge smaller pieces, breaking the copper along the perforation similar to a postage stamp.

Trammers, muckers and track men

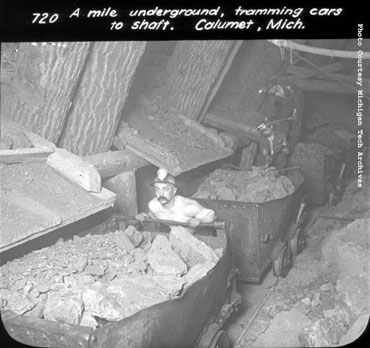

Once the rock was blasted away, men would load the broken ore into tram cars to be moved to the nearest shaft. In some mines, muckers did the work of shoveling the rock into tram cars, while trammers pushed them along rails to the shaft; in many mines, however, these two jobs were both done by the trammer. In later years, trammers also operated electric and battery-powered underground locomotives. Track men installed and maintained the small-guage rail tracks that the tram cars moved along.

Mucking and tramming were the most difficult and back-breaking jobs underground. As it required little skill to shovel rock and push heavy tram cars, these positions were often given to unskilled immigrants with little mining experiences. Early waves of Finnish immigrants often found themselves in this sort of work, and trammers were later drawn from the unskilled immigrants from Croatia, Slovenia and Italy.

In some mines, particularly the low-grade ore bodies of the Copper Range Company mines, rock was sorted underground so that only the most valuable pieces were hoisted to the surface. In these settings, pickers did the work of selecting the higher-value ore, while fillers moved waste rock to underground storage areas (often “filling” disused stopes with waste rock to help to prevent cave-ins). In some mines, wallers were used to stack waste rock into walls along underground tunnels.

Wood was used to construct shafts and to provide support underground. Timbermen were employed to move, cut, install and maintain wooden structures underground. These would include shaft timbers, “stulls” (support timbers, often the relatively untouched trunks of large trees) and square set timbering in which individual pieces of cut timber were formed into cube-like support structures. Although some historians feel it may be an ethnic stereotype, recent research confirms that French-Canadians comprised a high percentage of the timbermen in Michigan mining companies. Because of the danger of fire from dry timbers, sprinklers were employed to spray water and other fire-retardant chemicals onto wooden structures underground.

Surface superintendent, surface captain and surface bosses

Like the underground portion of a mine, the surface portions of the mine included a variety of activities and employees. Management of these functions was usually given to a single surface superintendent, with lower levels of responsibility assigned to surface captains and surface bosses. In the early years of Michigan’s copper district, superintendents were often American managers sent in to oversee the mine operations. It wasn’t long, however, before experienced non-American underground miners and mine captains ascended to fill these roles.

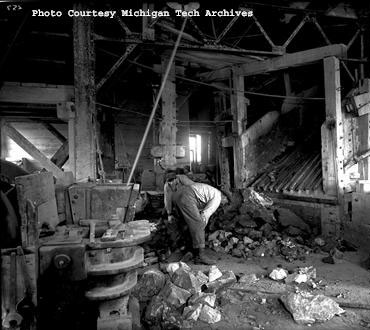

Rock house laborers, kiln men and car fillers

At the surface of the shaft, rock was dumped from ore cars and processed by rock house laborers – either in a separate rock house, or in a combination shaft-rockhouse. Ore was sorted by size (and sometimes by grade), put through different crushing machinery and sent to different storage bins. As with the underground work of mucking and tramming, rock house work was often considered unskilled and ethnic immigrants from Finland, Italy, Croatia and Slovenia were often employed in this back-breaking work.

In the early period of Michigan copper mining, many mines used kilns to heat piles of copper ore. Kiln men poured water onto the heated stone, causing the rock to shatter into small pieces that could be shipped to the stamp mill. Once rock was sorted, car fillers would load it into railroad or tram cars for shipment to the stamp mill.

Hoisting engineers, hoist tenders and wipers, landers and roll men

Hoists were used to raise ore from a mine and lowering men and supplies to the various working levels. Hoisting drums allowed lengths of cable to be unwound into the mine, with interchangeable vehicles attached to their cables: a “mancar” or “cage” would carry men, while rock skips and baling skips were used to lift ore and water (in the region’s early history, an iron bucket or “kibble” was also used to hoist rock and supplies). At the surface, a variety of personnel were required to operate and maintain these large pieces of machinery. Hoisting engineers were very important employees who had direct control of the hoisting engine and, therefore, were responsible for the lives of the men descending into the mine. Hoist tenders and wipers worked around hoisting engines, monitoring operations, checking for the wear of parts (such as braking mechanisms) and cleaning and filling various hydraulic fluids.

A lander was stationed at the mouth of the shaft and would assist men stepping from the mancar or assist laborers in removing supplies or loading rock skips (in some mines, landers also worked at each operating level underground). Roll men maintained wooden rollers within the mine shaft which carried the weight of the hoisting cable and helped to reduce the wear of this important commodity. Smaller underground hoists were also used to move materials between levels within in the mine.

Pump and compressor engineers, tenders and pipe men

Compressors produced compressed air used underground in the operation

of mechanized rock drills and other types of machinery. Use of this machinery

also helped to circulate foul air away from the working areas of the

mine. Rock drills also used water to keep down small particles of rock

and dirt which caused breathing and lung problems for underground workers.

Operation and maintenance of this equipment required a number of engineers,

tenders and pipe tenders

Firemen & boiler tenders

Supplies, equipment, men and rock were moved about the surface in a variety of ways. Some companies utlized teams of horses with different types of carts and vehicles; the use of horses (or teams of horses) was referred to as teaming and men employed in this work were sometimes referred to as teamsters.

The larger and more developed mines constructed small rail lines – or tramways – over which material could be moved in small wheeled cars. The largest of these companies also created fully-operational railroads. Some were private lines, working over privately-owned rail lines such as the Quincy and Torch Lake Railroad of the Quincy Mining Company and the Hecla and Torch Lake Railroad, operated by the Calumet & Hecla Copper Company. The Copper Range Company built the Copper Range Railroad, which served both as a private railroad for its mining operations and as a “common carrier” for smaller mining companies. The Copper Range also offered a passenger and freight service to the general public.

Like stamp mill operations and smelting works, the fully-functional railroads employed men in a variety of positions that are too numerous to detail here.

The surface workings of an active mining company included a large number of ancilliary operations. Historically, metal parts for machinery were not mass-produced so a company’s foundry, blacksmith shop and machine shop might employ foundrymen, smiths and machinists to use forges, anvils and machine tools to fabricate wheels, stamp shoes, rock skips, girders and other metal pieces.

Carpenters often worked in a mine’s dedicated carpenter shop to fabricate wooden items such as support timbers, shaft linings, and brake shoes for hoists.

Masons worked with stone, building foundations for buildings, support structures for railway lines and sometimes walls along underground tunnels.

Michigan copper mines were some of the first sites in the Upper Peninsula to install electricral systems. Electricians had the job of installing and maintaing electrical systems, including lighting and telephone lines, as well as high-voltage power to industrial equipment.

A master mechanic was often employed to oversee much of this surface work. For instance, when a new hoist was installed, the master mechanic might direct masons in constructing a foundation and assist carpenters and machinists in fabricating the machinery to be installed in the structure.

A specialized type of drilling equipment called a diamond drill was used to take samples of rock. Using a special hollow drill (with the tip coated in black diamonds), a diamond drill would bore a hole through the ground and remove a long tube of rock (usually called a core sample) that could be examined and tested for its metallic content. Diamond drills were sometimes used underground to explore the rock beyond the end of a tunnel, but were also used at the surface to test land purchases for possible new mineral deposits.

Underground workers had a locker room facility available to them near the shaft house. At the beginning of their shift, they could change out of their street clothes into working clothes before going underground. At the end of their shift, they could remove their clothing – which was usually wet from their underground work – and shower before dressing in their “dry” street clothes. Wet working clothes were left in the heated building (sometimes hung from chains near the ceiling) to dry overnight. As a result, this building was usually referred to as a “change house” or “dry house.” Men employed to work in these buildings were known as change house men or simply dry men.

Security was an issue at most mine locations, though the larger concern was usually against catastrohpic fires rather than left or sabotage. Companies which turned to outside insurance companies for fire insurance usually paid lower premiums if they employed watchmen who made regular rounds of buildings checking for signs of fire. Larger companies, such as the Calumet & Hecla were self-insured, but still employed large security forces to monitor their properties. Although most companies relied on community fire departments, some locations (particularly those which were remote from towns and cities) employed their own private firemen to fight fires that might arise at their industrial sites.

Surface laborers

Many of the specialized jobs listed in this section required specific

skills and experience. Most of the work on the surface of a mining operation,

however, was carried out by surface laborers who would paid a daily wage

and assigned to ever-changing (and often back-breaking) tasks. Surface

laborers might one day dig a ditch alongside a road or move several cords

of firewood to a boilerhouse; the next day they might lay a stone coarse

for a building foundation or move tons of waste rock to underfill a railway

trestle.

Mine superintendent / general manager

The mine superintendent or general manager was in charge of all of the company’s operations, both above and below ground. All of the functional operation managers reported to him – the mining captain, surface captain, master mechanic, chief mining engineer and chief clerk. The mine superintendent was the only direct link between the Michigan-based mining operation and the company’s corporate headquaters, which were often located in an East Coast city such as Boston, New York or Philadelphia.

Mine superintendents were very powerful and influtential men in the Copper Country. Individuals such as Charles Lawton, superintendent of the Quincy Mining Company, and James MacNaughton, general manager of the Calumet & Hecla Copper Company, were directly responsible for the lives of thousands of workers, the production of millions of pounds of copper and the profits of corporate shareholders.

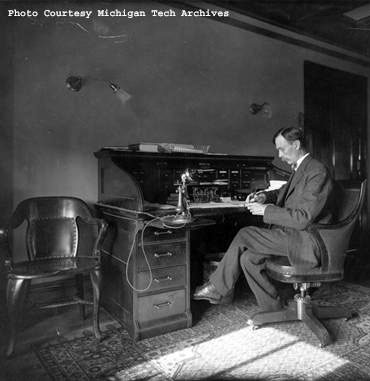

Chief Clerk, supply clerk and assistants

In modern usage, the word clerk usually refers to a menial or unskilled position. Historically, however, clerks were the accounting and financial experts within any corporation. The chief clerk at a mine was comparable to what we might see as a chief financial officer or controller in today’s corporate setting. The chief clerk would employ

Mining engineer, geologist, assayer and assistants

Horace Stevens applied the title mining engineer to “any man having sufficient ability to pass intelligently upon mineral values and to open and operate a mine, whether such ability were gained in a school or by practical experience.” After 1900, mining engineers were usually college-trained men who worked above ground in charge of all decisions about the mine’s underground workings. Graduates of mining schools, such as the Michigan Mining School in Houghton, often sign the letters M.E. after their name to indicate that they had received a college “Engineer of Mines” degree. An assayer conducted chemical tests on samples taken underground (or from diamond drill tests) to determine the exact content and value of any metal or metals in a specific part of the mine. These determinations assist the geologist in understanding the geology of the underground workings and help to determine future development of the mine workings.

Chief engineer, engineers, architects, draftsmen

Because of the remote location of Michigan’s copper district, much of the design and construction work for buildings, equipment and tools had to be done onsite. Many mining companies employed engineers, architects and/or draftsmen to draw and communicate needs to company machinists and carpenters. The Calumet & Hecla Copper Company even had its draftsmen design storage cases for their own blueprint collections – storage cabinets which were built by the company’s carpenters and housed in a headquaters building designed by company architects and built by company-employed stone masons.

Time keeper, stenographer & clerical assistants

Time keepers were the human predecessor of the modern time clock; instead of punching a card with a time clock, mine employees would stop at timekeeper’s office on their way to and from work. Records were kept for the amount of time each man worked – in some cases hours, in other cases days or even weeks. At the end of the month, information from “time books” was tallied to produce paychecks.

Mining company offices usually employed a number of stenographers and clerical assistants to help create, collect and organize the records of the company. Mines were in constant communication with their East Coast executive offices, as well as suppliers, machinery manufacturers and local merchants. Larger mines might also maintain correspondence between different functional units within their Michigan locations (mine, railroad, stamp mill, and smelter). The financial activity of the company was recorded in elaborate sets of ledgers, financial journals, account books and files. Toward the end of the Nineteenth Century, new concepts of cost analysis and efficiency encouraged companies to develop detailed accounts of all aspects of the mine’s activity which could allow calculation of costs associated with every man-hour of work done in the mine and for every pound of copper the company produced.

It is useful to note on this last section that stenography and clerical work were some of the only positions filled by women at Michigan copper mining companies.

Calumet and Hecla, Inc., Glossary of Terms, Calumet, Michigan: Calumet & Hecla, Inc. [ca. 1955].

Horace J. Stevens, editor, “Glossary of Mining Terms,” Copper Handbook, Volume VII, 1907, pages 137-167.

Paul W. Thrush, editor, A Dictionary of Mining, Mineral and Related

Terms, Washington, D.C.: United States Bureau of Mines, Department of

the Interior, 1968.